-

Effect of Co and Al Inconel 718 alloy on microstructure and mechanical properties

Inconel 718 alloy is a high-Nb age-strengthened Ni-Cr-Fe-based deformed high-temperature alloy with excellent high-temperature and mechanical properties and is widely used in aerospace and other fields. However, when the service temperature of Inconel 718 alloy exceeds 650°C, the γ” phase w...Read more -

Comparison of Inconel 625 and Incoloy 825

In industrial projects, the materials chosen are as important as the design. Two common alloys are Inconel 625 and Incoloy 825 alloy. Let’s compare these two materials so you can make an informed decision for your project. Alloy Inconel 625 and Alloy Incoloy 825 are nickel-based superalloys devel...Read more -

Inconel 725 VS Inconel 625: What’s the Difference?

Inconel 725 and Inconel 625 If you’re an engineer or metal fabricator, you know that when it comes to metals, performance matters. Inconel is a super alloy commonly used for its superior strength and corrosion resistance. But which type should you choose – Inconel 725 or Inconel 625? ...Read more -

Argon arc welding process of Hastelloy C276 and super duplex stainless steel 2507

Nowadays, the level of shipbuilding has been greatly improved, and the design and construction of marine desulfurization towers has become a trend. However, how to ensure the welding quality of super duplex stainless steel and Hastelloy alloy dissimilar materials has always been a problem. To thi...Read more -

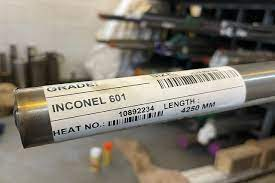

What is the difference between Inconel 601 and Inconel 625?

Inconel 601 vs. Inconel 625: What’s the difference? Inconel alloy is a nickel-chromium based superalloy with excellent corrosion resistance, heat resistance and strength. Inconel 601 and Inconel 625 are both widely used materials in aerospace, nuclear engineering and chemical processing industrie...Read more -

How to weld Inconel?

Inconel is a highly corrosion-resistant alloy that performs extremely well in extreme environments. Inconel is a registered trademark of the Special Metals family. They are registered as austenitic nickel-chromium-based superalloys. Inconel alloy maintains high tensile strength even at the meltin...Read more -

Active element effect: the key to improving the oxidation resistance of high-temperature alloys

Adding trace amounts of active elements to high-temperature alloys, such as rare earth elements, Ti, Zr, Hf, etc., can significantly reduce the oxidation rate and increase the adhesion between the oxide film and the matrix, thus significantly improving the oxidation resistance of high-temperature...Read more -

What material is Alloy 20?

Alloy 20 (UNS N08020), also known as Carpenter 20, is a nickel-iron-chromium stainless steel alloy. This steel is austenitic, meaning it cannot be hardened by heat treatment. It has corrosion resistance and good mechanical properties at low and high temperatures. Let’s take a closer look at the c...Read more -

Research and application of oxidation of high temperature alloys

The oxidation of high-temperature alloys refers to the process in which high-temperature alloys react with oxidizing media at high temperatures to form oxides. At high temperatures, the oxidation reaction accelerates rapidly and is destructive to high-temperature alloy parts. Therefore, it is ver...Read more -

What is the difference between Inconel 82 and Inconel 625?

Inconel is a superalloy containing nickel, chromium and molybdenum, with other elements added for specific industrial applications. When selecting a superalloy for a specific engineering need, it is important to understand the differences between the different types of alloys. Let’s take a look a...Read more -

UNS N02200 – Composition, properties and uses

Nickel Alloy 200 is a metal that is highly resistant to corrosion and has excellent mechanical and physical properties. It is widely used in various fields such as chemical processing, electronics and aerospace. This article will introduce the composition, mechanical and physical properties, uses...Read more -

The secrets and applications of high-temperature alloys

## The secrets and applications of high temperature alloys With the development of science and technology and the progress of industry, high-temperature alloys are playing an increasingly important role in various fields. They are widely used in aviation, aerospace, automotive, electric power and...Read more